Headstay systems

-

Furling systems

-

Racing foils

Headstay Systems

Electric

Bamar

EJF

- Compact shape and reduced dimensions.

- Higher torque, very low maintenance, simple installation, which improve safety and comfort onboard.

- Very high mechanical performance (epicyclic system).

- Electric motor with electromagnetic brake.

- Manual emergency clutch does not rotate when the system is electrically operated.

- For 1x19 wire stay diameter 8-26mm.

- For max. rod # -48, -76/-91 or -115/-150

Tack adapters

In order to fit Bamar electric motorization to the existing foils, Bamar have created a series of tack adapters.

Facnor

EF Features:

- Wired or radio remote control

- Waterproof drive unit

- No specific maintenance required

- Optimized power (max 800W, speed 30t/min)

- Low energy consumption

- Reduced noise level

- Fitted over the existing forestay without cutting

- EF motorization kit for converting Facnor manual furling gears (LS/LX200 to 330)

- Available in 12 and 24V with inversing box

| Maksimalna debljina sajle | ||||||

|---|---|---|---|---|---|---|

| Model | EF 470 | EF 600 | ||||

| Max. boat length | 12- 18 m / 40 - 60 ft | <16m / <55 ft | ||||

| Max. forestay diameter | 12 - 14 mm | 22 mm | ||||

| Forestay length | 18,5 m | 20,5 m | ||||

| 20,5 m | 22,5 m | |||||

| 24,5 m | ||||||

Harken

MKIV 2E - 3E features:

- High-strength materials

- Sculpted design

- High torque motor

- Low maintenance and power consumption

- Easy to install or upgrade from MKIV 2 or 3 units

- Strong foil joints

- 12 or 24 V system

- Emergency manual operation

| Model | Wire | Rod | Forestay length |

|---|---|---|---|

| MKIV 2E | 8 - 10 mm | -12, -17, -22 | standard: 18,57 m max.: 20,70 m |

| MKIV 3E | 11 - 12 mm | -22, -30 | standard: 22,88 m max.:25,02 m |

Profurl

NDE features:

- Large range of systems

- Cruising and racing versions available

- Great comfort with minimum effort

- Easy installation on the existing forestay

- Minimal sound

- Low power consumption

- No special maintenance

- Possibility to convert a manual Profurl furler into a motorised system with the motorisation kit

- Instant manual operation in case of emergency

- The self-locking, non-reversible mechanism prevents accidental unfurling

- Easily adjustable position of the system to the deck

- Available in 12V or 24V, with possibility to chose the furling direction

Cruising models with round profile

| Model | NDEC 420 | NDEC 430 | NDEC 480 | NDEC 520 | NDEC 530 |

|---|---|---|---|---|---|

| Boat length | 13 - 15 m | 14 - 16 m | 14,5 - 18,5 m | 16,5 - 18,5 m | 18,5 - 26 m |

| Forestay diameter | 10 mm | 12,7 mm | 14,3 mm | 16 mm | 19 mm |

Racing models with black extrusion and oval profile

| Model | NDER 420 | NDER 430 | NDER 480 |

|---|---|---|---|

| Boat length | 13 - 15 m | 14 - 16 m | 14,5 - 18,5 m |

| Forestay diameter | 10 mm | 11,1 mm | 12,7 mm |

Reckmann

EF90 features:

- For yachts of approx. 36-70 foot in length

- For wire forestays from 8 to 16 mm in diameter (alternatively rods -12 to -76)

- The self-braking worm gear is nearly maintenance free

- Easy to switch over to manual operation

- Integrated length adjustment, works even with the sails unfurled

- High performance and top efficiency in simple and comfortable operation

- Quiet operation

- Top quality materials

- Aluminium or carbon profiles available

| Model | EF 90-2 | EF 90-2 | EF 90-3 | EF 90-3 |

|---|---|---|---|---|

| Max. wire diameter | 10 mm | 12 mm | 14 mm | 16 mm |

| Max. rod size | -17 | -30 | -48 | -60 |

| Max. forestay length | 18 m | 23 m | 27 m | 31 m |

| Sail size | <80 m2 | <120 m2 | <160 m2 | <220 m2 |

| aluminium profile | R20 | R30 | R40 | R50 |

| Carbon profile | S2.5 | S3 | S4 / S4.5 |

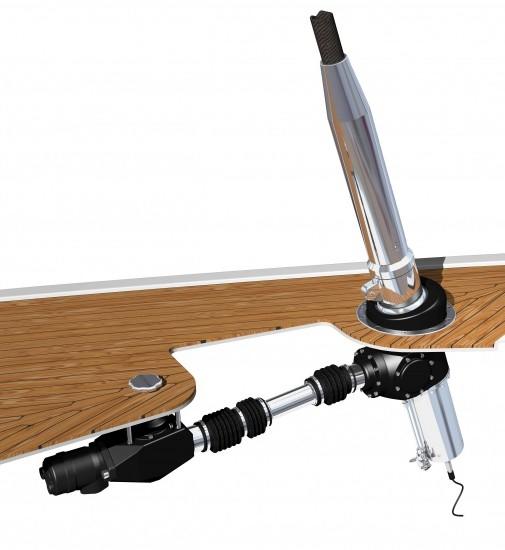

UDe features:

- A below deck mounted electric furling gear

- The UD unit is fixed in the deck, no chainplate is needed

- Maintenance free

- Electronic position indicator

- The emergency manual drive mounted on deck level with a standard winch handle

- Compact system size

- Ultrasonic sensor to know where the adjuster piston is and how the stay is adjusted

- Good performance to weight ratio

- The system is available for PBO and rod stay

- Stay disconnection system above deck level

- Suitable for carbon and aluminium foils

| Max. wire diameter | 14 mm | 16 mm |

|---|---|---|

| Max. rod size | -48 | -60 |

| Max. forestay length | 27 m | 31 m |

| Sail size | <150 m2 | <190 m2 |

| Aluminium profile | R40 | R50 |

| Carbon profile | S3 | S4 / S4.5 |

Certified Service Center

We are a part of the network members inside BSI Group as a Certified Service Center

As a service center, we follow BSI’s recommendations and guidelines. We are fully backed by the factory and we only use BSI supplied, or approved, materials when doing the refits for new or previously supplied BSI projects. This ensures complete visibility and history of all materials installed in the rigging package.